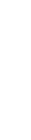

Elements, commonly known as teeth are the uniformly shaped parts of the zipper, that engage with eachother or are fit into eachother when they run through a slider. ![]()

Tape, like the name suggest is a long strip of cloth . This tape is exclusively made for zipper . Tape is mostly made out of polyester , however can be made from cotton or vinyl if required.

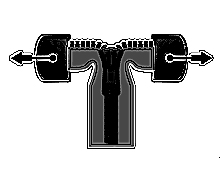

Slider is a component used to join or separate the elements/teeth of a zipper. Various forms of sliders are available according to the application.

Bottom or Top stops are placed at the bottom or top end of the zipper in order to stop the slider from escaping out of the ends of the elements. Bottom stops can be made in different combinations according to the application of the zipper.

As we custom make each order according to buyers requirements and different buyers have varied requirements with respect to size , colour , type etc . We want to make sure that all aspects or factors are covered while placing order. ![]()

After we have once made a zipper it cannot be altereded. Hence we would like to share with you a checklist of some technical and commercial requirements which should not be missed when placing a zipper order :

Kindly specify whether you require metal zipper, polyester coil zipper or molded zipper and the element/teeth size - #3, #5, #7 or #8 . It is very important to identify whether the application demands open end, close end , two way , h type or type zipper making .

Please specify whether non-lock, pin-lock or auto-lock slider is required . In case of customized sliders, a special mention is a must.

It is to be noted that length of zipper is not measured from top teeth to bottom most teeth or the top of the tape to the bottom of the tape but it is measured from top of the to stop to the bottom of the bottom stop or box pin.

There are two ways to choose colours . The first being you can choose a colour from our shade card of 140 colours and place your order as per the shade number . Second is , that you couid send a swatch of atleast 2*2 inch in case of DTM( dyeing to match) processing .

Please mention quantity in pieces , dozens or rolls, required by type , colour and size.

As we specialize in customizing zipper as per customer requirements . We can provide metallic finishes in polyester coil zipper and molded zipper. We can also provide various finishes in metal zipper and sliders.

Kindly make sure the communications are clear regarding delivery date. Both buyer and supplier should be on the same page when it comes to goods processing time and delivery time period.

Please mention any special requirements in advance. Although we use the best raw material available, we would still recommend a special mention in advance in case of AZO free , nickel free or any specific metal free when placing the order .

4.1 : We, at Titan Zip Fasteners have very stringent quality tests . However it is very important to test zippers in actual conditions before applying them to the product. In case there are any issues after stitching the zipper to the product, it is entirely the customers responsibility . ![]()

4.2 : It is very important to make sure there is enough clearance for slider to move freely after stitching to the garment .

4.3 : Use of rubber band to store zippers should be prohibited.

4.4 : Zippers with plastic stoppers should be used for baby products .

4.5 : Appropriate size and type of zipper to be used based on load and end use .

4.6 : Our zippers are not suitable for over dyeing.

4.7 : One half of a particular zipper should not be interchanged with another zipper .

4.8 : Any problems that occur due incorrect application/usage of a zipper is not the responsibility of Titan Zip Fastener.

![]()

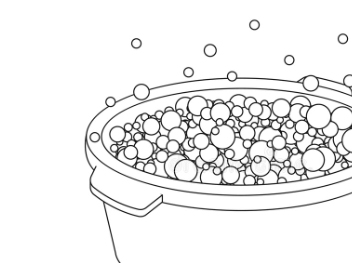

5.1 : Zipper should be completely closed before washing.

5.2 : Garments should be turned to its reverse side before washing. ![]()

5.3 : The right proportions of chemicals should be used while washing .

5.4 : Washing time to not be exceeded – 30 minutes

5.5 : Washing temperature to not be exceeded – 150*

5.6 : Final washing should be done after stone washing

5.7 : Garments should be dried immediately after washing and not left wet .

5.8 : If garment has to undergo chemical washes with strong alkali we recommend to do a sample test as it may react with surface coating on metal zippers.

5.9 : Dark coloured zipper might affect colour of light coloured garment if washed with harsh chemicals.

5.10 : If garment has to undergo sever washing , kindly avoid use of autolock sliders.

5.11 : In case of link in the sliders, the puller movement should be arrested before putting into washing in order to avoid any damage to the puller link .

5.12 : We donot recommend enamel painted zipper for any wash down process like stone wash , enzyme wash etc

![]()

6.1 : Ironing temperature to not exceed 110 degree celcius .

6.2 : Direct contact of the zipper elements or bottom/top stops with the iron can lead to paraffin stains or melting the elements . Please avoid direct contact by placing a cloth on the concerned part of the zipper .

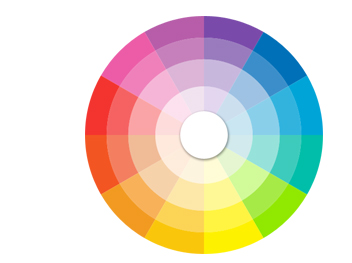

We at Titan Zip Fastener Industries, have the latest state of art machinery paired with highly experienced and qualified technicians . We provide zippers colour matching to the garment swatch provided by buyer . We can provide 3 colour options for the type of zipper required and the buyer can choose the closest match of the three . Moreover the dyes and chemicals used in dyeing process are the best in class . ![]()

All tested AZO free and test reports can be provided as per customer demand. However there are certain preconditions , principles and technicalities to be understood when placing an order for DTM zipper. Please help us provide the best in industry color matching by abiding to the following :

7.1 : Kindly specifiy the light source/light box in which the colour of the zipper is to be matched to the colour of the swatch.

7.2 : Please send atleast 2*2” of swatch for colour matching.

7.3 : Please specify which side of the garment to be used for matching.

7.4 : In case of dual shaded swatch , must mention which shade to be matched to or which yarn to matched to weft or warp.

Please note that different fabrics reflect light differently as per their properties hence it is to be understood that two different fabrics can not have the exactly same colour .

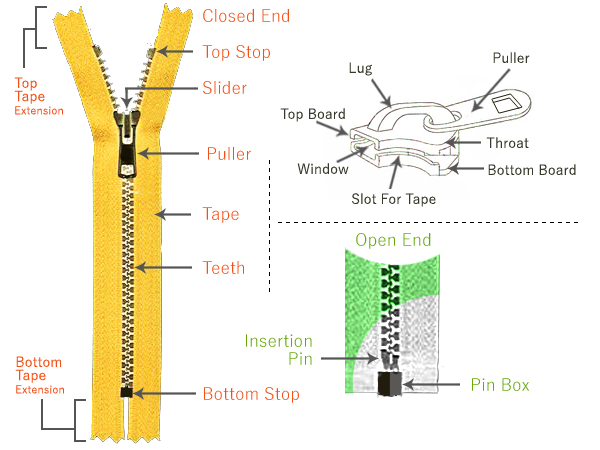

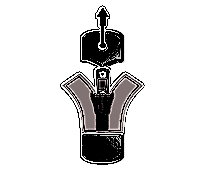

Our purpose here is to determine the load that the puller can bear. A slider sample is fixed to the bottom jaw as showed in the image and the puller is pulled at 90 degree at constant speed. Maximum force at dis-assembly is recorded.

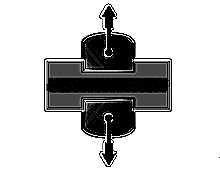

The purpose of this test is to determine the force at which the top stop releases it self and enables the slider to separate from the zipper . Top stop of a sample zipper is fully closed. A suitable fixture pulls the slider in the direction of the seperation of the elements. The maximum force is recorded when the slider or puller comes away from the chain.

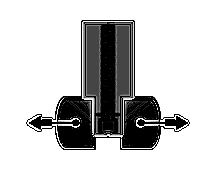

The purpose of this test is to determine the force at which the bottom stop releases it self and enables the slider to run out of the elements of a zipper .The slider or puller of a zipper sample is fully unzipped. The top of each side of the zipper are held by a fixture right from the middle . The slider is pulled at a constant speed until the slider breaks away from the chain, the maximum force is recorded.

The purpose of this test is to identify the quality and strength of the box and pin . Tape on both parts is pulled at a constant speed as shown in the picture. Maximum force at disassembly of the pin and box is recorded.

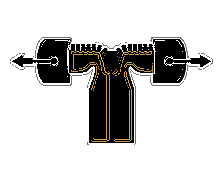

The purpose of this test is to determine the force at which the elements on both the sides of the zipper are disintegrated .This test is used to check the lateral strength of the zipper . A zipper sample is closed completely and fixed to the testing machine. The hand/parts of the machine hold the tape from both the sides and pulls them apart at a constant force which keeps increasing. The maximum force is recorded when the elements disengage or leave the tape .

This test is specific to lock sliders to test the strength of the locks . Tapes on both sides of half unzipped zipper sample are placed in the middle the hands of the testing machine that holds it firmly. The machine pulls apart each side of the zipper into opposite directions at a constantly increasing force . and maximum force is recorded at the failure of the lock system.

This test aims at determining the number of times a zipper can be zipped and unzipped before it ceases to function peroperly . The sample zipper is placed in the testing machines. After it has been setup lateral and longitudinal tension is applied while the slider zips and unzips the zipper repeatedly . A specified number of such cyclic operations are done to test the durability of the zipper .